What is left over after the process is complete is a. It is a natural process and is well understood by mankind, having been harnessed for many years.

, The anaerobic digestion and bioresources association (adba) reported that 100 biogas plants were built in 2016. Anaerobic digestion systems for livestock manure operate to reduce methane emissions, odors,.

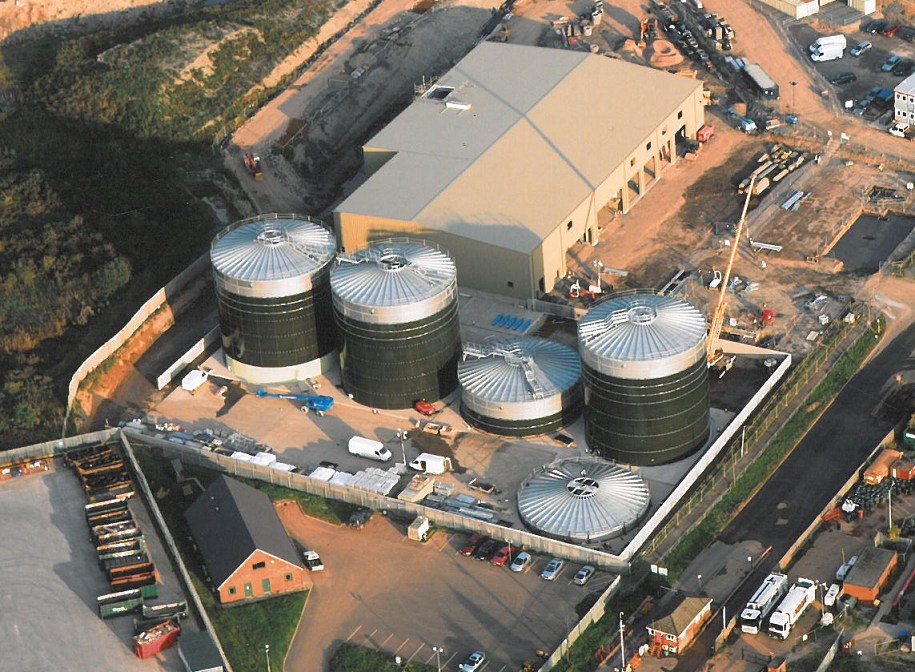

Massive anaerobic digestion plant in UK with biomethane injection YouTube From youtube.com

Massive anaerobic digestion plant in UK with biomethane injection YouTube From youtube.com

Anaerobic digestion happens in closed spaces where there is no air (or oxygen). It may have been used to heat water as early as the 10th century bc and the first plant was built in bombay, india in 1859. 2021/07/12 although anaerobic digestion of small amount of organic and food waste was considered unprofitable a few years ago, it is growing today with a new model of biogas production: One of the major pros of anaerobic digesters is that it can offer a constant power supply to the universe.

Massive anaerobic digestion plant in UK with biomethane injection YouTube One of the major pros of anaerobic digesters is that it can offer a constant power supply to the universe.

Today in western and central europe over 15,000 digesters, primarily agricultural, convert manure and other organic waste into electricity and. One of the major pros of anaerobic digesters is that it can offer a constant power supply to the universe. In this instance, “organic” means coming from or made of plants or animals. Anaerobic digestion (ad) plants vary in their cost of construction, but some guidance of costs can be provided.

Source: greencitytimes.com

Source: greencitytimes.com

Using anaerobic digestion technologies can help to reduce the emission of greenhouse gases in a number of key ways: Not only completed but also commissioned in the intervening period to the end of september 2017. Anaerobic digestion is recognised by the government, defra, the welsh assembly, the scottish. What is left over after the process is complete is a. What is Anaerobic Digestion? Green City Times.

Source: fineartamerica.com

Source: fineartamerica.com

Most estimates have been made to include not just the ad equipment to produce the biogas, but also for an adjacent combined heat and power (chp) plant. The following is an overview based on organic waste stream type (manure, municipal wastewater treatment, industrial wastewater treatment and municipal solid waste): This takes place naturally or in an anaerobic digester. Many different anaerobic digester systems are commercially available. Wastetoenergy Anaerobic Digestion Plant Photograph by Robert Brook.

Source: johnkinggroup.co.uk

Source: johnkinggroup.co.uk

The ad process begins when organic material is put inside a sealed tank or digester. So, methane or biogas is the name of the gas. “the plant should be fed evenly over 24 hours, with the silage fed through a diet feeder like a machine and the slurry through an agitator pump. The plant will produce biogas using grass silage and cattle slurry. Wakefield Anaerobic Digestion Plant JK Fabrications John King Group.

Source: agriland.ie

Source: agriland.ie

Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses. Anaerobic digestion (ad) converts plant matter (biomass) into gas for use as a source of heat and electricity and more recently after upgrading to biomethane it is a sustainable renewable vehicle fuel. Anaerobic digesters are also called “biodigesters” to retain the reference to a biological digestion process with fewer words. The anaerobic digestion and bioresources association (adba) reported that 100 biogas plants were built in 2016. 103 Anaerobic Digestion plants approved in Northern Ireland as AD.

Source: cstindustries.com

Source: cstindustries.com

Anaerobic digestion (ad) plants vary in their cost of construction, but some guidance of costs can be provided. 2021/07/12 although anaerobic digestion of small amount of organic and food waste was considered unprofitable a few years ago, it is growing today with a new model of biogas production: Anaerobic digestion is the process by which organic matter such as animal or food waste is broken down to produce biogas and biofertiliser. Anaerobic digestion systems for livestock manure operate to reduce methane emissions, odors,. Wet Anaerobic Digestion Allows EFW Plant to Generate Almost 25,000.

Source: waste-management-world.com

Source: waste-management-world.com

Anaerobic digestion (ad) is the controlled natural breakdown of organic materials into methane, carbon dioxide gas and fertiliser. Using anaerobic digestion technologies can help to reduce the emission of greenhouse gases in a number of key ways: Not only completed but also commissioned in the intervening period to the end of september 2017. Most estimates have been made to include not just the ad equipment to produce the biogas, but also for an adjacent combined heat and power (chp) plant. First English Food Waste Facility to Pass Anaerobic Digestion.

Source: bsg-ecology.com

Source: bsg-ecology.com

Biogas from anaerobic digestion is an important source of renewable energy. Anaerobic digestion systems for livestock manure operate to reduce methane emissions, odors,. For instance, every cow is estimated to. Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses. Appropriate Assessment of Anaerobic Digestion Facilities, Ireland BSG.

Source: ukconstructionmedia.co.uk

Source: ukconstructionmedia.co.uk

For instance, every cow is estimated to. Anaerobic digestion happens in closed spaces where there is no air (or oxygen). Anaerobic digestion is a biological process during which microorganisms digest organic waste such as food waste, farm manure, or sewage sludge, and turn it into biogas and biological fertiliser. The ad process begins when biomass is put inside a sealed tank or digester. UK's largest Anaerobic Digestion Plant UK Construction Online.

Source: colloide.com

Source: colloide.com

It may have been used to heat water as early as the 10th century bc and the first plant was built in bombay, india in 1859. Anaerobic digestion is the process by which organic matter such as animal or food waste is broken down to produce biogas and biofertiliser. The ad process begins when biomass is put inside a sealed tank or digester. Once inside the ad tank, microorganisms break down the materials and digest the biomass. Anaerobic Digestion Systems Colloide Engineering.

Source: blog.anaerobic-digestion.com

Source: blog.anaerobic-digestion.com

“the plant should be fed evenly over 24 hours, with the silage fed through a diet feeder like a machine and the slurry through an agitator pump. One of the major pros of anaerobic digesters is that it can offer a constant power supply to the universe. Biogas systems develops and builds anaerobic digestion plants for safe. Anaerobic digestion is the process by which organic matter such as animal or food waste is broken down to produce biogas and biofertiliser. Anaerobic Digester for Sale Biogas Digestion Plant Selection for All.

Source: irishnews.com

Source: irishnews.com

The plant will produce biogas using grass silage and cattle slurry. Anaerobic digestion is the process by which organic matter such as animal or food waste is broken down to produce biogas and biofertiliser. The ad process begins when organic material is put inside a sealed tank or digester. Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses. £23m worldfirst anaerobic digestion plant in Ballymena will deal.

Source: eadt.co.uk

Source: eadt.co.uk

Our plant will start out using about 70% waste feedstock, which could be increased. Using anaerobic digestion technologies can help to reduce the emission of greenhouse gases in a number of key ways: Biogas from anaerobic digestion is an important source of renewable energy. The following is an overview based on organic waste stream type (manure, municipal wastewater treatment, industrial wastewater treatment and municipal solid waste): Multimillion pound deal to buy anaerobic digestion plant on Norfolk.

Source: bioenergy-news.com

Source: bioenergy-news.com

Once inside the ad tank, microorganisms break down the materials and digest the biomass. • replacement of fossil fuels • reducing or eliminating the energy footprint of waste treatment plants The process releases biogas, (mainly. One of the major pros of anaerobic digesters is that it can offer a constant power supply to the universe. Anaerobic Digestion The Digester Bioenergy Insight Magazine.

Source: waste-management-world.com

Source: waste-management-world.com

2021/07/12 although anaerobic digestion of small amount of organic and food waste was considered unprofitable a few years ago, it is growing today with a new model of biogas production: It is a natural process and is well understood by mankind, having been harnessed for many years. Since there is a continuous production of the waste materials used for the digestion process, anaerobic digestion can ensure a steady source of electricity generation. The ad process begins when biomass is put inside a sealed tank or digester. Agrivert Opens Largest Anaerobic Digestion Plant in Wales Waste.

Source: youtube.com

Source: youtube.com

2021/07/12 although anaerobic digestion of small amount of organic and food waste was considered unprofitable a few years ago, it is growing today with a new model of biogas production: It may have been used to heat water as early as the 10th century bc and the first plant was built in bombay, india in 1859. Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses. It is a machine used to intentionally replicate this process and capture the biogas produced by the anaerobic bacteria as a byproduct of digestion. Massive anaerobic digestion plant in UK with biomethane injection YouTube.

Source: recyclingwasteworld.co.uk

Source: recyclingwasteworld.co.uk

In this instance, “organic” means coming from or made of plants or animals. Anaerobic digestion is a sequence of processes by which microorganisms break down biodegradable material in the absence of oxygen. Since there is a continuous production of the waste materials used for the digestion process, anaerobic digestion can ensure a steady source of electricity generation. It is a machine used to intentionally replicate this process and capture the biogas produced by the anaerobic bacteria as a byproduct of digestion. Wales opens its largest anaerobic digestion plant.

Source: opusenergy.com

Source: opusenergy.com

Anaerobic digestion is the process by which organic matter such as animal or food waste is broken down to produce biogas and biofertiliser. For instance, every cow is estimated to. Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses. The ad process begins when organic material is put inside a sealed tank or digester. An illustrated guide to anaerobic digestion Opus Energy.

Source: j-h-a.co.uk

Source: j-h-a.co.uk

Not only completed but also commissioned in the intervening period to the end of september 2017. The ad process begins when biomass is put inside a sealed tank or digester. One of the major pros of anaerobic digesters is that it can offer a constant power supply to the universe. Anaerobic digestion is a biological process during which microorganisms digest organic waste such as food waste, farm manure, or sewage sludge, and turn it into biogas and biological fertiliser. Anaerobic Digestion Plant Development John Hill Associates.

Source: architectsdatafile.co.uk

Source: architectsdatafile.co.uk

Anaerobic digestion (ad) plants vary in their cost of construction, but some guidance of costs can be provided. Our plant will start out using about 70% waste feedstock, which could be increased. It also lowers greenhouse gas emissions. It is a machine used to intentionally replicate this process and capture the biogas produced by the anaerobic bacteria as a byproduct of digestion. Anaerobic digestion plant expansion sees the best of everything.

Source: eastmidlandsbusinesslink.co.uk

Source: eastmidlandsbusinesslink.co.uk

2021/07/12 although anaerobic digestion of small amount of organic and food waste was considered unprofitable a few years ago, it is growing today with a new model of biogas production: Not only completed but also commissioned in the intervening period to the end of september 2017. Anaerobic digestion is the natural process in which microorganisms break down organic materials like manure. Most estimates have been made to include not just the ad equipment to produce the biogas, but also for an adjacent combined heat and power (chp) plant. Nottinghamshirebased anaerobic digestion plant given a sustainable.

Source: engineerlive.com

Source: engineerlive.com

It also lowers greenhouse gas emissions. Anaerobic digestion (ad) plants vary in their cost of construction, but some guidance of costs can be provided. It may have been used to heat water as early as the 10th century bc and the first plant was built in bombay, india in 1859. Anaerobic digestion is the natural process in which microorganisms break down organic materials like manure. Anaerobic digestion plant design Engineer Live.

Source: opusenergyblog.com

Source: opusenergyblog.com

Anaerobic digestion is the natural process in which microorganisms break down organic materials like manure. What is left over after the process is complete is a. Many different anaerobic digester systems are commercially available. For instance, every cow is estimated to. The illustrated stepbystep guide to anaerobic digestion.

Explaining what ad is, matthew said: Once inside the ad tank, microorganisms break down the materials and digest the biomass. The ad process begins when biomass is put inside a sealed tank or digester. Biogas systems develops and builds anaerobic digestion plants for safe. UK's 'largest' onsite anaerobic digestion plant comes online.

Source: johnkinggroup.co.uk

Source: johnkinggroup.co.uk

Anaerobic digestion is the process by which organic matter such as animal or food waste is broken down to produce biogas and biofertiliser. Anaerobic digestion is a biological process during which microorganisms digest organic waste such as food waste, farm manure, or sewage sludge, and turn it into biogas and biological fertiliser. It may have been used to heat water as early as the 10th century bc and the first plant was built in bombay, india in 1859. The following is an overview based on organic waste stream type (manure, municipal wastewater treatment, industrial wastewater treatment and municipal solid waste): Wakefield Anaerobic Digestion Plant JK Fabrications John King Group.

Source: peterdann.com

Source: peterdann.com

Today in western and central europe over 15,000 digesters, primarily agricultural, convert manure and other organic waste into electricity and. Anaerobic digestion happens in closed spaces where there is no air (or oxygen). Using anaerobic digestion technologies can help to reduce the emission of greenhouse gases in a number of key ways: The initials “ad” may refer to the process of anaerobic digestion or the. Anaerobic Digestion Plant Peter Dann.

Explaining What Ad Is, Matthew Said:

[1] the process is used for industrial or domestic purposes to manage waste or to produce fuels. It may have been used to heat water as early as the 10th century bc and the first plant was built in bombay, india in 1859. If that rate of completion of anaerobic digestion plants (in the uk) had been maintained an additional 150 plants would have been completed. This tends to reduce fossil fuel usage.

Biogas Systems Develops And Builds Anaerobic Digestion Plants For Safe.

Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses. Once inside the ad tank, microorganisms break down the materials and digest the biomass. 2021/07/12 although anaerobic digestion of small amount of organic and food waste was considered unprofitable a few years ago, it is growing today with a new model of biogas production: Many different anaerobic digester systems are commercially available.

Using Anaerobic Digestion Technologies Can Help To Reduce The Emission Of Greenhouse Gases In A Number Of Key Ways:

It is the natural process of collecting gases from decaying organic material. “the plant should be fed evenly over 24 hours, with the silage fed through a diet feeder like a machine and the slurry through an agitator pump. It is a natural process and is well understood by mankind, having been harnessed for many years. The initials “ad” may refer to the process of anaerobic digestion or the.

The Anaerobic Digestion And Bioresources Association (Adba) Reported That 100 Biogas Plants Were Built In 2016.

Not all materials break down at the same speed, and. Anaerobic digestion happens in closed spaces where there is no air (or oxygen). Anaerobic digestion (ad) converts plant matter (biomass) into gas for use as a source of heat and electricity and more recently after upgrading to biomethane it is a sustainable renewable vehicle fuel. The process releases biogas, (mainly.